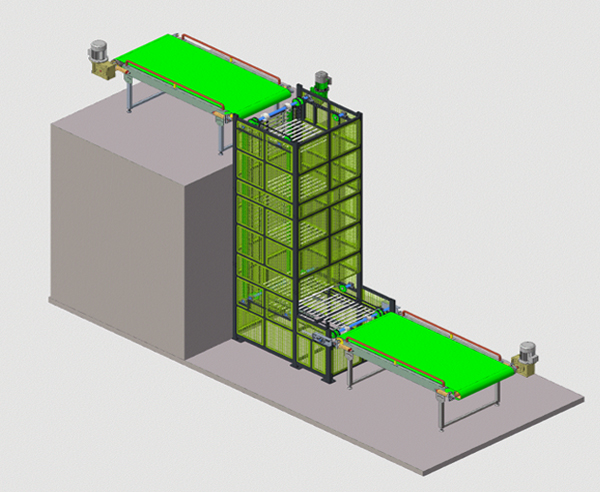

Continuous Vertical Conveyor (CVC)

Our Continuous Vertical Conveyor is an industrial material handling system designed to transport products or materials between different elevations, typically in a vertical direction. Unlike traditional conveyors, which operate along horizontal paths, continuous vertical conveyors move items upwards or downwards, maintaining a steady flow of materials throughout the process.

Note: This equipment is suitable for shifting light weight material continuously from floor to floor & not with multiple floor level.

Key Features and Design

- Continuous Movement:As the name suggests, continuous vertical conveyors are engineered to run non-stop, facilitating the efficient transport of goods over long distances. The system never halts, ensuring constant material movement without the need for frequent starts and stops.

- Elevator-Like Operation: These conveyors often resemble vertical lifts or elevators, but instead of lifting only a few items at a time, they are designed for bulk movement. The conveyor system can use chain mechanisms.

- Space-Saving Design: Vertical conveyors are highly beneficial in environments with limited floor space. They make use of vertical height, reducing the need for large horizontal areas and optimizing the layout of production or storage facilities.

- Modular Construction: Many vertical conveyors are modular, meaning their components can be easily adjusted or replaced. This modularity allows customization in terms of size, capacity, and speed.

Advantages:

- High Capacity: Vertical conveyors can move large volumes of materials, making them suitable for industries that need to handle high throughput, such as food processing, logistics, and mining.

- Efficient Use of Space: Because they operate vertically, they allow facilities to maximize available space. This is especially important in warehouses or manufacturing plants where floor area is limited.

- Reduced Labor Costs: By automating the vertical transport process, these conveyors reduce the need for manual labour, improving efficiency and safety within the workplace.

- Versatility: Continuous vertical conveyors can be adapted to handle a wide range of materials, from lightweight boxes to bulk materials like sand or grain. This makes them highly versatile across different industries.

Applications:

- Manufacturing and Assembly Lines: In factories, vertical conveyors are used to transport components between different levels of a production line, saving time and ensuring a smooth flow of materials.

- Logistics and Warehousing: They are used in warehouses to move goods between floors, especially when there is a need to transport items from storage areas to order fulfilment stations.

- Food and Beverage Industry: These conveyors are common in the food processing industry, where they are used to move products like packaged goods, bottles, or raw ingredients vertically through different processing stages.

- Mining and Agriculture: Bucket elevators are widely used in mining and agriculture to transport bulk materials such as ores, grain, and other agricultural products.

Considerations:

- Load and Capacity: When choosing a continuous vertical conveyor, it’s essential to evaluate the maximum load capacity required. Overloading can result in mechanical failure or inefficient operation.

- Speed and Control: Conveyor speed should be matched to the speed of other processes in the system. Too fast a speed can led to accidents or spillage of materials, while too slow a speed can affect overall productivity.

- Maintenance: Continuous vertical conveyors require regular maintenance to ensure their smooth operation. Belt wear, motor issues, or mechanical breakdowns should be checked periodically.

- Safety: Proper guarding and safety mechanisms should be in place to prevent accidents, such as entanglement in the conveyor system or falling materials.

TECHNICAL SPECIFICATION

| CVC Type | C-Type (Same Side) Z Type (Opposite Side) |

| Max. Carriage Size | 800 x 800 mm |

| Min. Size | 200 x 200 x 30 mm |

| Loading Material | Carton Box, Plastic Crate, Gunny Bags |

| Max. Throughput | 1200 pph |

| Speed | 12-14 m/min Variable |

| Weight Range | 0.05 – 60 kg |

| Min. Infeed Level | 750 mm |

| Max. Height | 10m |

| Lifting Mechanism | Chain drive |

| Peripheral Equipment | Infeed & Outfeed Conveyor |

| Control System | PLC/VFD Based |

| Control Voltage | 24 VDC |

| Design | Standard, Customized |

| Color | Any |

| Brand | Technovision |

| Condition | New |